How Hoe Gifts Delivers Scalable OEM Solutions for Global Markets

In the global decorative gift and home décor industry, technical manufacturing capability is no longer optional—it is the foundation of long-term OEM and wholesale partnerships. Buyers sourcing from a hanging ornaments manufacturer, glassware OEM supplier, or mixed material home decor factory are no longer focused solely on price. Instead, they evaluate suppliers based on process stability, material engineering, scalability, and compliance with international retail standards.

As a professional custom decorative gifts OEM, Hoe Gifts has built its manufacturing systems around these evolving expectations, supporting global retailers, brand owners, and licensed programs with technically driven production solutions.

The Global Market Context: Why Manufacturing Capability Matters

According to data from Statista, the global home décor and giftware market exceeded USD 800 billion in 2023, with seasonal and decorative products accounting for a rapidly growing share. Meanwhile, McKinsey & Company reports that over 70% of global retail buyers prioritize supply chain reliability and quality consistency over unit price when selecting long-term manufacturing partners.

This shift has reshaped the role of OEM factories. Today, a competitive glassware OEM supplier or kitchenware wholesale manufacturer must operate not only as a producer, but as a technical partner capable of managing materials, processes, and risk at scale.

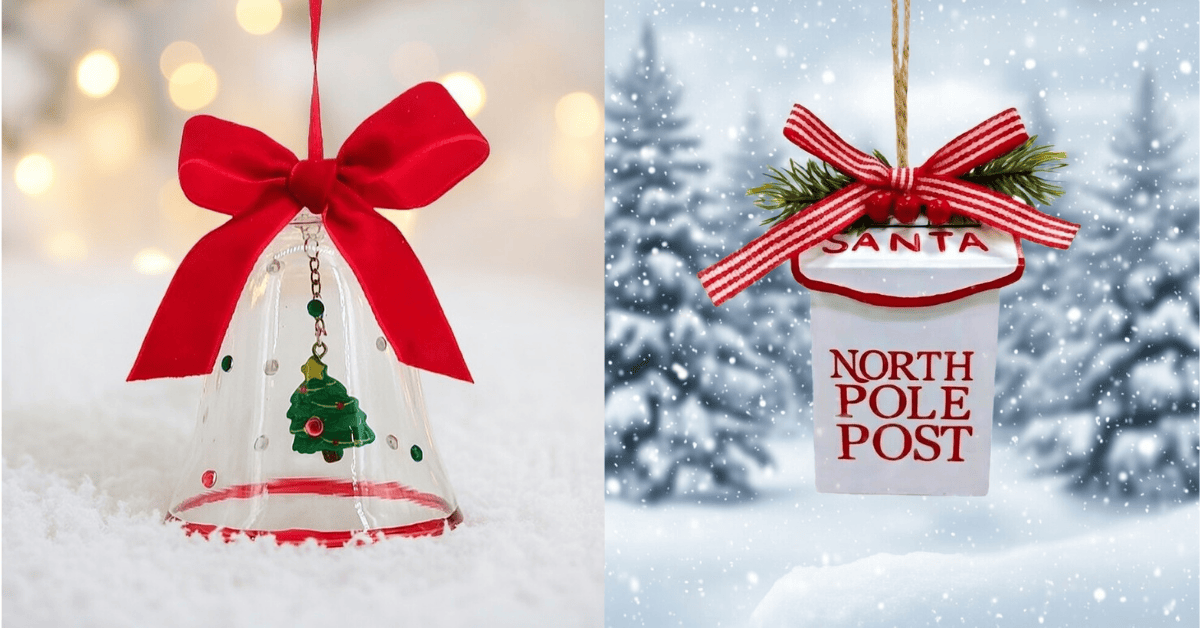

Hanging Ornaments Manufacturing: Precision at Scale

As a specialized hanging ornaments manufacturer, Hoe Gifts focuses on balancing handcrafted aesthetics with industrial-level consistency.

Decorative hanging ornaments—especially glass-based or mixed-material designs—require tight control over:

-

Material purity and thickness

-

Weight balance and suspension stability

-

Surface finishing and decorative detailing

-

Packaging protection for long-distance logistics

Industry studies published by Smithers indicate that breakage rates in decorative glass products can exceed 5–7% without proper process control and packaging optimization. To mitigate this risk, Hoe Gifts integrates in-process inspections and packaging validation early in development, rather than relying solely on final checks.

This approach enables reliable mass production while preserving the visual refinement expected in premium holiday and seasonal décor programs.

Glassware OEM Supplier: Material Science Meets Process Control

As a glassware OEM supplier, Hoe Gifts applies material-focused engineering to ensure long-term product performance.

Glass remains one of the most preferred materials for decorative and functional products due to its:

-

Optical clarity and light refraction

-

Long-term color stability

-

Full recyclability and sustainability advantages

According to the Glass Packaging Institute, glass can be recycled indefinitely without quality degradation, making it increasingly attractive for eco-conscious retail programs.

From a technical perspective, Hoe Gifts controls:

-

Glass composition consistency

-

Temperature management during forming

-

Surface stress reduction to improve durability

These controls are essential for scalable OEM production, especially when supplying large retailers with repeat seasonal programs.

Kitchenware Wholesale Manufacturer: Function Meets Durability

As a kitchenware wholesale manufacturer, production priorities extend beyond appearance to include usability, safety, and lifecycle performance.

Kitchen-related products must meet:

-

Dimensional accuracy for daily use

-

Heat and moisture resistance

-

Stable surface finishes suitable for frequent handling

Data from Euromonitor International shows that kitchenware products with higher durability ratings achieve up to 30% higher reorder rates in wholesale channels.

Hoe Gifts integrates functional testing and material selection reviews during product development, ensuring that decorative kitchen items meet both aesthetic and performance expectations across global markets.

Mixed Material Home Décor Factory: Engineering Complexity into Stability

Operating as a mixed material home decor factory introduces a higher level of technical complexity. Combining glass, metal, zinc alloy, silicone, resin, or textiles requires precise coordination between different processes and suppliers.

Key challenges include:

-

Material expansion and contraction differences

-

Adhesion compatibility

-

Assembly tolerance control

Hoe Gifts addresses these challenges through structured assembly workflows and experienced production teams assigned to material-sensitive processes. This enables the creation of visually rich products without compromising structural integrity—an essential requirement for international shipping and retail handling.

Custom Decorative Gifts OEM: From Design to Retail Execution

As a custom decorative gifts OEM, Hoe Gifts supports both OEM and ODM projects with a development-driven approach.

According to Deloitte, products developed with early manufacturer involvement reduce production delays by up to 25% and lower quality-related returns by 20%. This insight reinforces the importance of integrating design feasibility, material optimization, and packaging considerations from the outset.

Hoe Gifts collaborates with clients across:

-

Concept development

-

Material and structure optimization

-

Cost-performance balancing

-

Retail-ready packaging solutions

This integrated workflow ensures that products are not only visually appealing, but also manufacturable at scale under fixed retail timelines.

Built for Global Retail Standards

Large retailers and licensed programs demand more than production capacity. They require:

-

Predictable quality performance

-

Repeatability across batches

-

Clear documentation and communication

Hoe Gifts aligns its manufacturing systems with international retail expectations, enabling long-term partnerships with global buyers across North America and Europe.

Conclusion: Manufacturing as a Strategic Advantage

In today’s competitive market, success as a hanging ornaments manufacturer, glassware OEM supplier, kitchenware wholesale manufacturer, or mixed material home decor factory depends on technical depth rather than surface-level capability.

By combining material expertise, disciplined process control, and scalable production systems, Hoe Gifts delivers dependable OEM solutions that support global retail programs, seasonal collections, and custom decorative gift initiatives.

For brands seeking a custom decorative gifts OEM partner focused on long-term value rather than short-term output, manufacturing excellence is the true differentiator—and it is where Hoe Gifts continues to invest.